June 2023 Newsletter (Removing adhesives)

Andy Harrison2023-05-26T16:50:21+01:00Have you ever struggled taking up adhesive?

Wow what a year so far! The Terrcos have been doing well, and our ever-popular Husqvarna HTC range are rarely in. We also had a shortage of our HTC 450, 110-v floor grinders which are the most popular single-phase floor grinders on the market. I would guess that about 25% of these hires are to remove products like bitumen and adhesive. But if flooring product removing and prep is outside of your daily comfort zone it can be a pain to get rid of. Here’s a few tips and tricks we have learnt along the way.

TOP TIP: You’re near the end of the job, you only have grinding diamonds and you’ve come across a little bit of stubborn adhesive. If the product’s not for budging and it’s just resetting on top of your diamonds, try spreading a thin layer of sand or equivalent grainy product on top, and then grind. This will help to clean the adhesive off the diamonds and has a chance to mix with the adhesive and create a paste which the grinder will find easier to cut through.

Tooling: There are 3 types of tooling we stock. PCD’s, Crushed PCD’s and diamond shoes.

When the adhesive has partially removed and bare concrete (around 40% of the floor or more) is showing a 16g diamond is the best shoe to use. The problem with using diamonds on this type of product is the adhesive or bitumen may heat up, clog the diamonds, and spread back onto the floor surface. This is why you need bare concrete showing to keep the diamond clean.

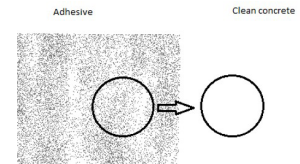

ANOTHER TIP: If the diamonds were working and have gradually stopped working, more than likely they are clogged up and so can no longer cut. When grinding ‘swing’ the grinder into the adhesive and then back onto bare concrete like the image below; this will help to keep the tooling clean.

Swing the grinder left to right from the adhesive to clean concrete and then back again.

Hybrid PCDs: Use when removing adhesive or bitumen under 1 mm thick. These are diamond blocks with PCD’s crushed in them. Excel at removing thinner product but do not cause a lot of damage to the surface, this makes it easier to grind out the marks when applying a coating.

PCD’S: The best shoes when grinding adhesives and bitumen. These have 2 protruding nodules that scrape the product up rather than grinding it down. This prevents it from heating and spreading. This may cause a bit of damage to the substrate, so we recommend you remove 60-70% of the product with these and the remaining 30%, grind with diamond shoes. This is normally the quickest and most effective way to remove bitumen and adhesive flooring products. Which machine? What tooling? We’ll gladly advise. Click our logos to head to our website!