The Importance of Hiring the Right Vacuum Dust Control Unit

The Importance of Hiring the Right Dust Vacuum Control

If a vacuum dust control unit isn’t working at close to 100% efficiency, it could be one of the most dangerous machines on site, and you wouldn’t even know it.

Surface preparation machines are notorious generators of huge quantities of health threatening airborne dust particles; a risk to workers and bystanders alike.

To combat that, vacuum dust control units are an effective solution to mitigate this danger.

Their effectiveness hinges on regular servicing and testing. Failure to do this, compromises the unit’s efficiency and exposes individuals to an array of hazards.

This article delves into the dangers of using unmaintained units in construction settings, shedding light on the potential consequences of overlooking proper upkeep.

Potential Implications of Dust Vacuum Control

Monitoring Efficacy

The efficacy of a vacuum dust control unit hinges on meticulous maintenance and regular testing.

Failure to uphold standards results in a myriad of hazards, undermining the intended purpose of the device.

The primary risk associated with neglected maintenance is diminished suction power.

Over time, dust accumulation within the unit’s filters and hoses impedes airflow, rendering the unit less effective and consequently, workers are exposed to heightened levels of dust, increasing the likelihood of respiratory ailments.

Maintenance & Regular Testing

To avoid the dangers associated with poorly maintained vacuum dust control units, flooring and construction companies must implement a regular maintenance and testing regime.

Regular testing of the electrics, suction and filters, as well as thorough cleaning will pick up potential issues before they escalate.

Additionally, adherence to manufacturer’s guidelines regarding filter replacement and system calibration is imperative to ensure optimal performance.

How to be Safe Using a Dust Vacuum Control

These machines are not complex to operate, but there are a few basic do’s and don’ts to adhere to, to avoid leakages and performance problems.

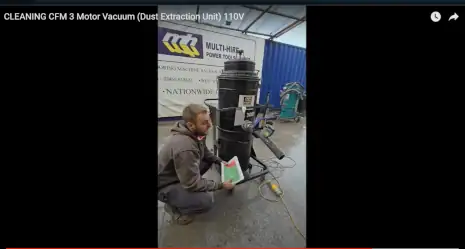

For that reason, on all our vacuum hire fleet we attach a QR code that links to the instructional video on our YouTube channel Instructional video.

Multi-Hire takes customer safety seriously. With every hired vacuum, you’ll be assured that it has been thoroughly tested before it’s let out to site.

The tests are calibrated suction, outlet gauge, filter saturation and electrical PAT test as well as a thorough filter and casing cleaning. These rigorous tests apply, no matter how short the previous hire was. Does that sound a little OCD?

Multi-Hire can offer you a similar facility to clean and test your own vacuum dust control units. Please call us to discuss and receive a quote.

The calibrated suction test checks the airflow from the vacuum. This indicates if the power is reduced.

If it is, this might be caused by a motor at end of life, a damaged or worn filter, damaged seals or a loose connection on the bodywork.

Hire a Dust Vacuum Control

In conclusion, the dangers of utilizing unmaintained vacuum dust control units in construction settings cannot be overstated.

From compromising respiratory health to posing environmental and regulatory risks, neglecting proper upkeep of these devices can have dire consequences.

Construction and flooring companies must recognise the importance of proactive maintenance and testing protocols to safeguard worker well-being and uphold regulatory compliance.

By prioritizing safety and adherence to industry standards, we can mitigate the hazards associated with airborne dust exposure in construction environments, ensuring a healthier and safer workplace for all. In short, cutting corners is not worth the risk.

YouTube Video